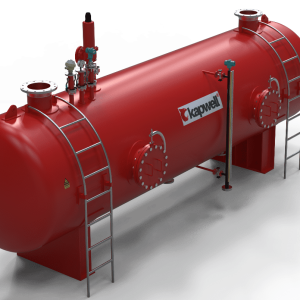

3 Phase separators are pressure vessels used to divide fluids into three phases: gas, oil and aqueous. They are usually designed to remove associated gas and oily water from crude oil, and after this first rough separation, oil can be sent to further treatment.

They are designed with the principle that each phase has a different density. The gas comes out from the top of the vessel, crude oil remains in the middle, while water settles down on the bottom together with any entrained solid (such as slugs, sand or debris). The two liquid phases need a specific residence time to allow the creation of two separate layers.

The selection of the internals depends on the characteristics of the incoming fluids: calming baffles, plate packs, water boot, vane or plate coalescers will be selected case by case.

Add your review